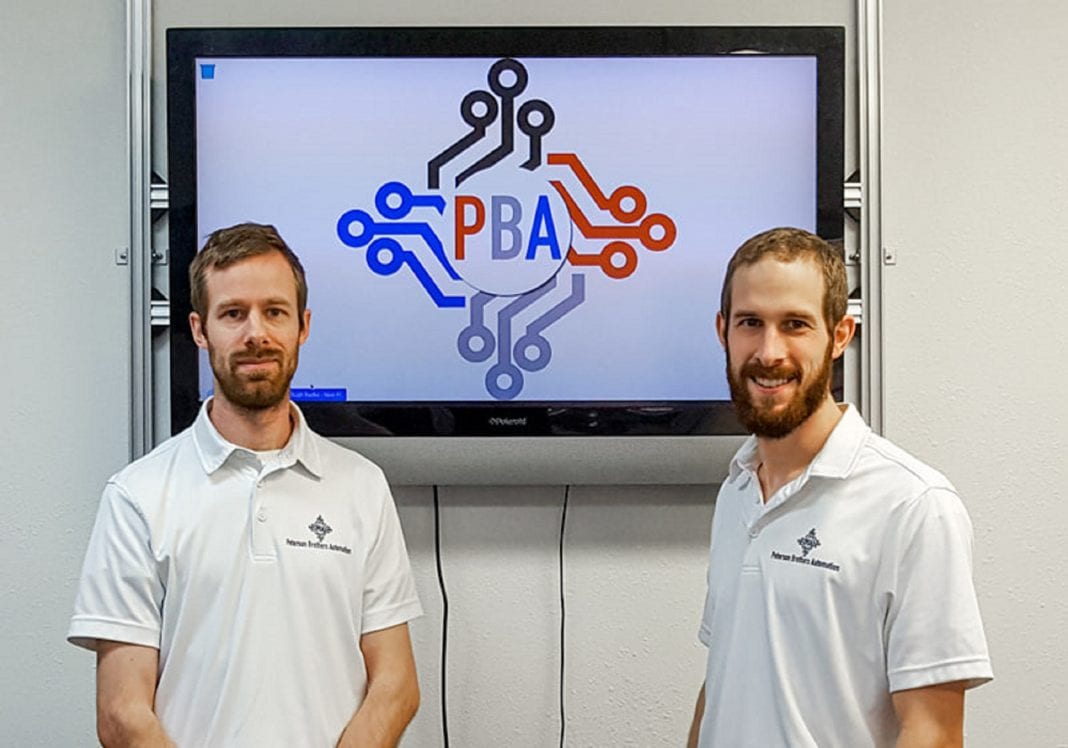

Go build some stuff could be David Peterson’s life motto. At 22 years old he started as a professor at Centralia Community College in the Robotics program. For eight years he worked there building one of the first mechatronics programs in Washington. Each year he saw 10 to 15 graduates equipped and hired directly into their field.

David’s brother, Jonathan Peterson has experience working as an automation engineer with Amazon and local lumber mills. His primary job was making all of their equipment “talk together” or networking.

“The stuff they are doing at the lumber mill is way ahead of anything they are doing at Amazon,” said Jonathan. At Amazon, the plan has to be perfect and work every time, in multiple locations. At a lumber mill, there is the flexibility to make systems work better immediately.

“Every operation has something to do with the internet,” said David. Collecting information as simple as transaction data is essential to the modern business world. However, it can be overwhelming to think about how to get business online. “We want to fix that,” he said.

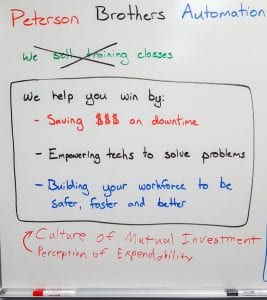

Combining David’s academic background and Jon’s corporate experience they launched Peterson Brothers Automation. The Chehalis based business specializes in customized, hands-on, industrial training that empowers businesses to create networking systems and solve problems along the way. In their first six months, they’ve already worked with local lumber mills, Cardinal Glass and Boeing.

“I didn’t realize just how expensive downtime was,” said David. Downtime is the time spent unable to perform business functions because of malfunctioning equipment or network failure.

To get a specific number to represent all company costs of downtime is difficult to do, but David found some research done on the automotive industry in 2018. “They looked everywhere from GM with 10 billion-plus per year revenue, down to the ones that were about several hundred thousand dollars revenue,” said David. The average cost was $22,000 per minute. Renting a private jet to collect broken parts is less expensive than waiting for repairs to be delivered for some companies.

To give a more local example, downtime can affect a business as small as a latte stand. If the coffee machine stops working, it takes time to call someone to come in and fix it. During that time there are immediate customers lost. However, even after the machine is running again there may be customers who choose not to return to that stand. They may recall the stand did not have a functioning machine the previous time and choose somewhere else.

The Petersons recognize teaching a company how to use a product is only a temporary fix for an ongoing need. “We teach people how to think about a problem and troubleshooting,” said David, “They’re never going to see the same problem twice, but they are going to see something that is like what they saw before.”

A lot of company training can be two days of presentations in a monotonous voice. “Literally they could have just emailed the PowerPoint and it would have been just as good,” said David. Instead, the Peterson’s have built a set of eight panels that have common networking components on them. Their training focuses on teaching attendees how to wire up the panels to complete various functions. “It’s homework using their hands instead of a book,” said David. This approach gives real-life experience for what will happen in their facility. Even attendees who were skeptical at first are hooked by the end of the day.

Photo credit: Kia Huffman

Every company is of a different size and will have different needs. “Our offering is usually one-day classes that are very customized,” said David. The fact that Peterson Brothers Automation is local to Lewis County gives them the ability to physically come to the facilities they work with. They personally create training based on the unique situations that could arise in that environment.

In addition to private classes, PBA also offers a YouTube channel with practical information such as what happens inside of a GFCI outlet. Another video covers “Why do capacitors blow up?” and shows one exploding in slow motion.

“The number one thing I’m most excited about is I now have the ability to go meet people in the community,” said David. He envisions meeting up with local small businesses and taking a look at whatever automated machines they are working with, just to learn more.

“I want to keep it local,” said David. “Technology makes the world a really small place.” The location of Chehalis makes it possible for PBA to travel to Seattle, Yakima and Portland to make connections.

However, the choice to stay in Lewis County is more than that. The brothers grew up in Adna, both attended Centralia College and worked at businesses in town. Jon currently lives in Boistfort and David lives with his wife and four children in Winlock. “This is home,” said David.

To contact Peterson Brothers Automation, email Jon at jon@PetersonBrosAutomation.com or call or text at 360-880-4435. For fun updates like their Facebook page.